Do you know how much it cost to clean your plant last night?

Every Carlson Engineering client knows this. Find out how.

Can you recall any product and trace it through your plant? Do you know what equipment it has touched?

The managers at the Meijer Purple Cow Dairy can. It’s easy.

Can you replay every HMI graphic screen and research every customer complaint?

The managers at several Nestle ice cream plants can. So can their operators.

Can you verify that your plant meets food safety guidelines using information automatically gathered from your plant floor?

The managers at Dannon can. They standardized on Carlson’s CIP HD, Track HD, and Instant Replay tools to automatically gather, process and store information directly from plant floor operations.

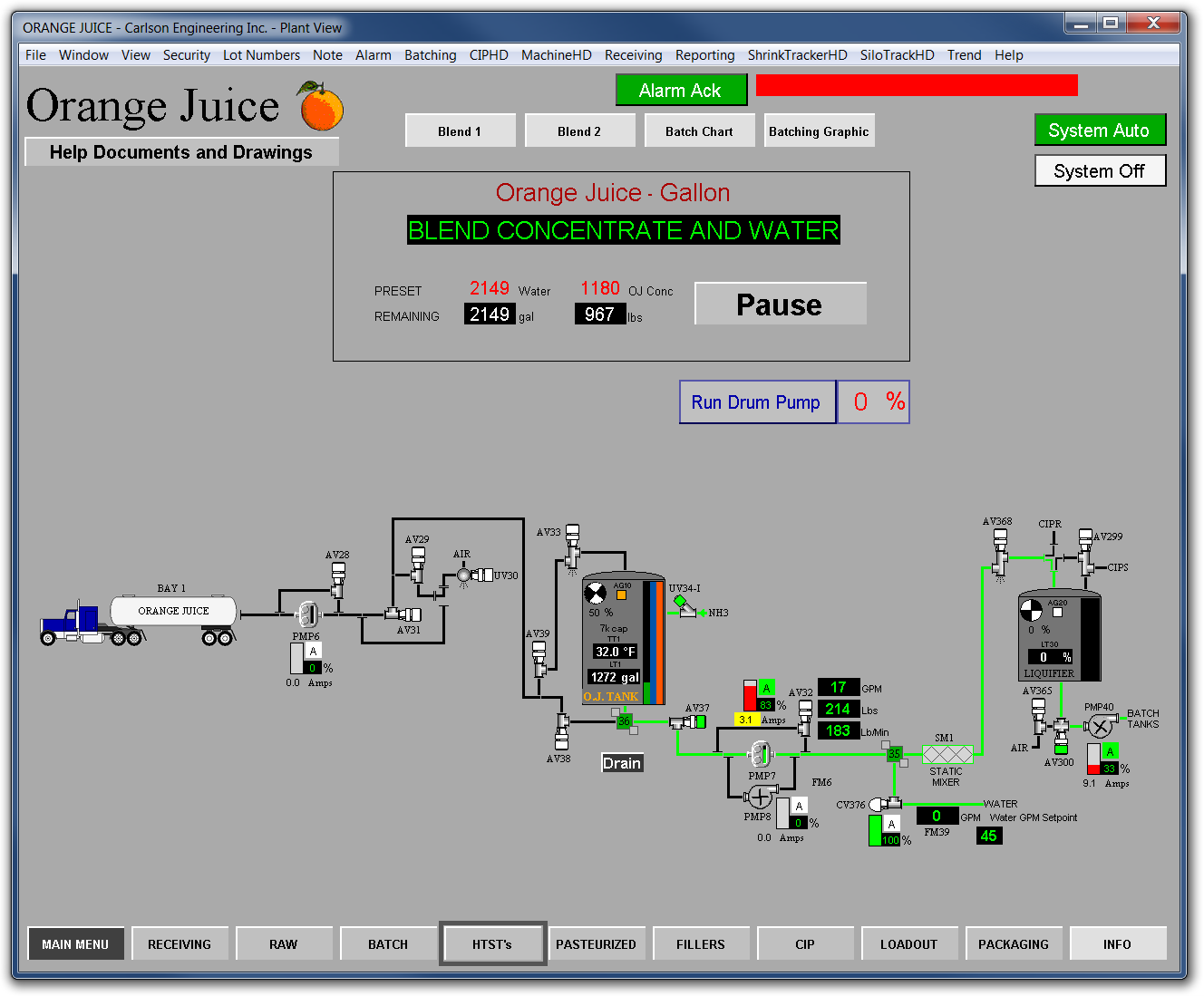

Integrated HMI and SCADA Package

- Includes control of all sanitary process applications

- Full featured; runs entire plant from receiving to filling

- Management reports & charting available on every desktop

- Integrates entire plant; eliminates complex software layers

- Configuration driven; simplifies programming & maintenance

- Open architecture; no locks; anyone can maintain

- NO HIDDEN SCRIPTS; no need for VB programming

- Commercial “off the shelf” application, no need for extra programming

- One-time site wide license. No expensive software licensing & application support fees

Comprehensive HMI/SCADA Process Control

- Receiving

- Tank Farm Manager

- Scheduling

- Routing

- Batching

- In Line Blending

- Recipe Management

- Pasteurizing/Homogenizing

- Filling

- Dosing

- Conveying

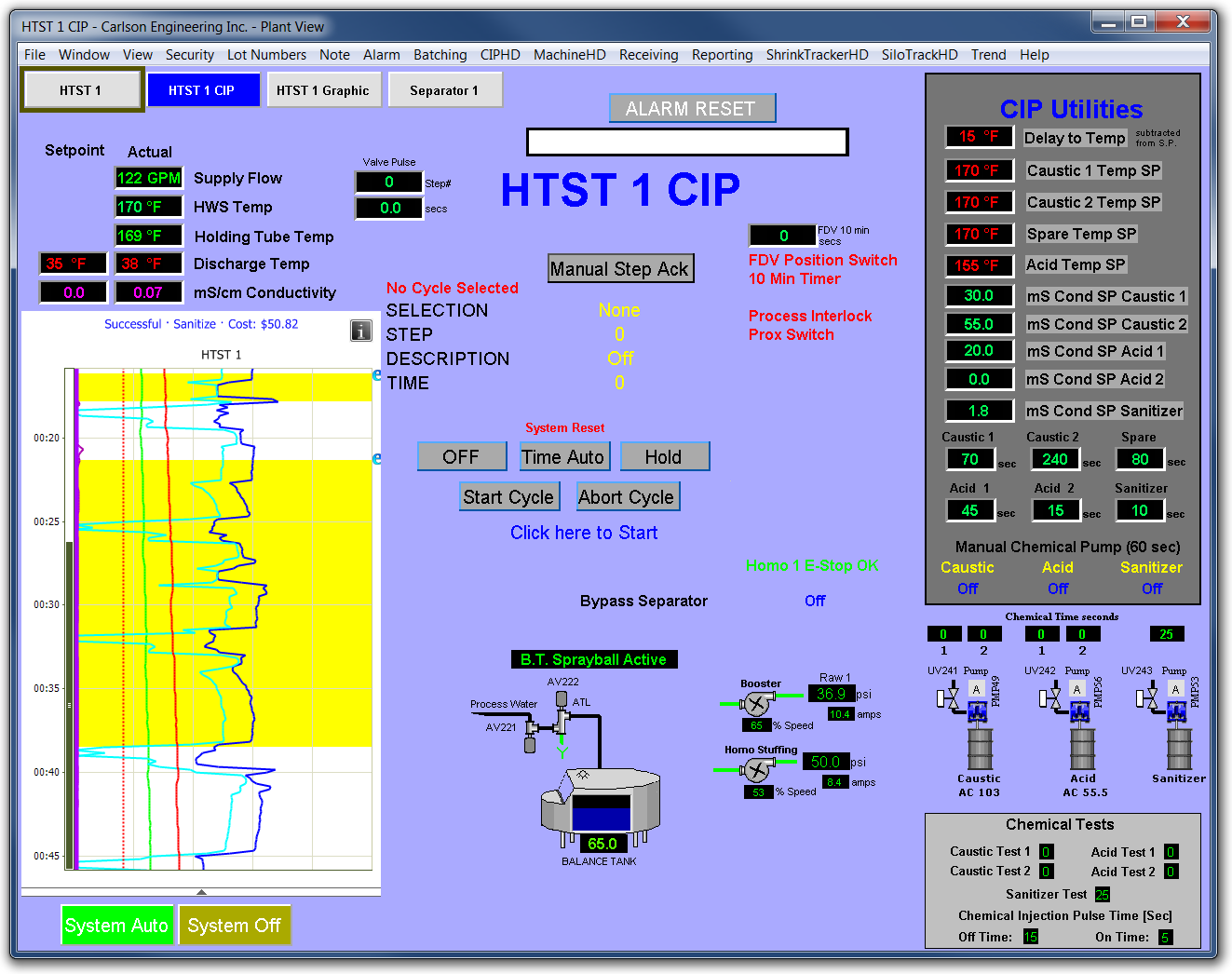

- Clean In Place

- Utilities Control

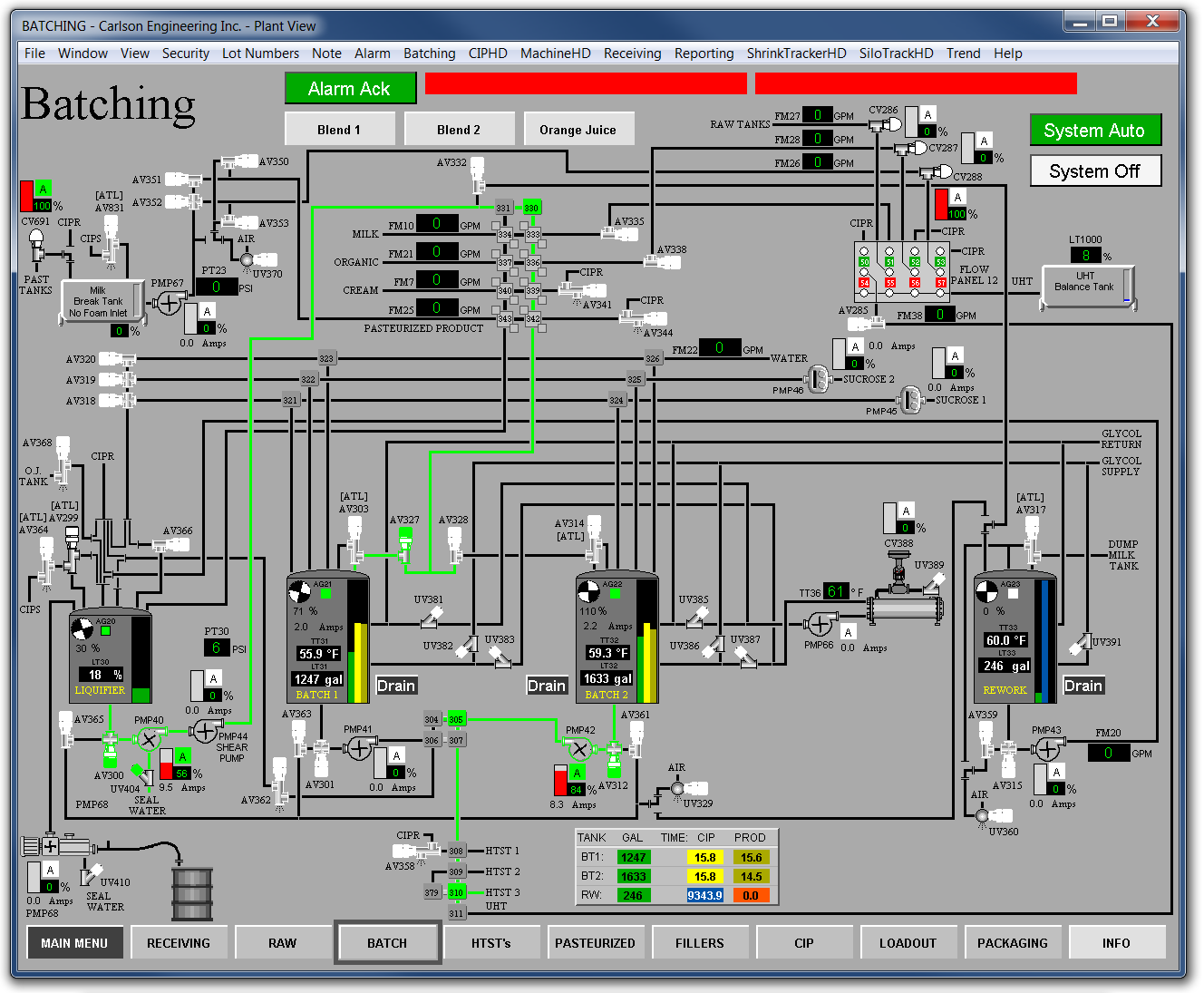

Batching

- Predictable & consistent batching control across your entire process.

- Easy drop down menus simplify and error proof operator selections

- Built-in recipe management stores product formulations and process pre-sets

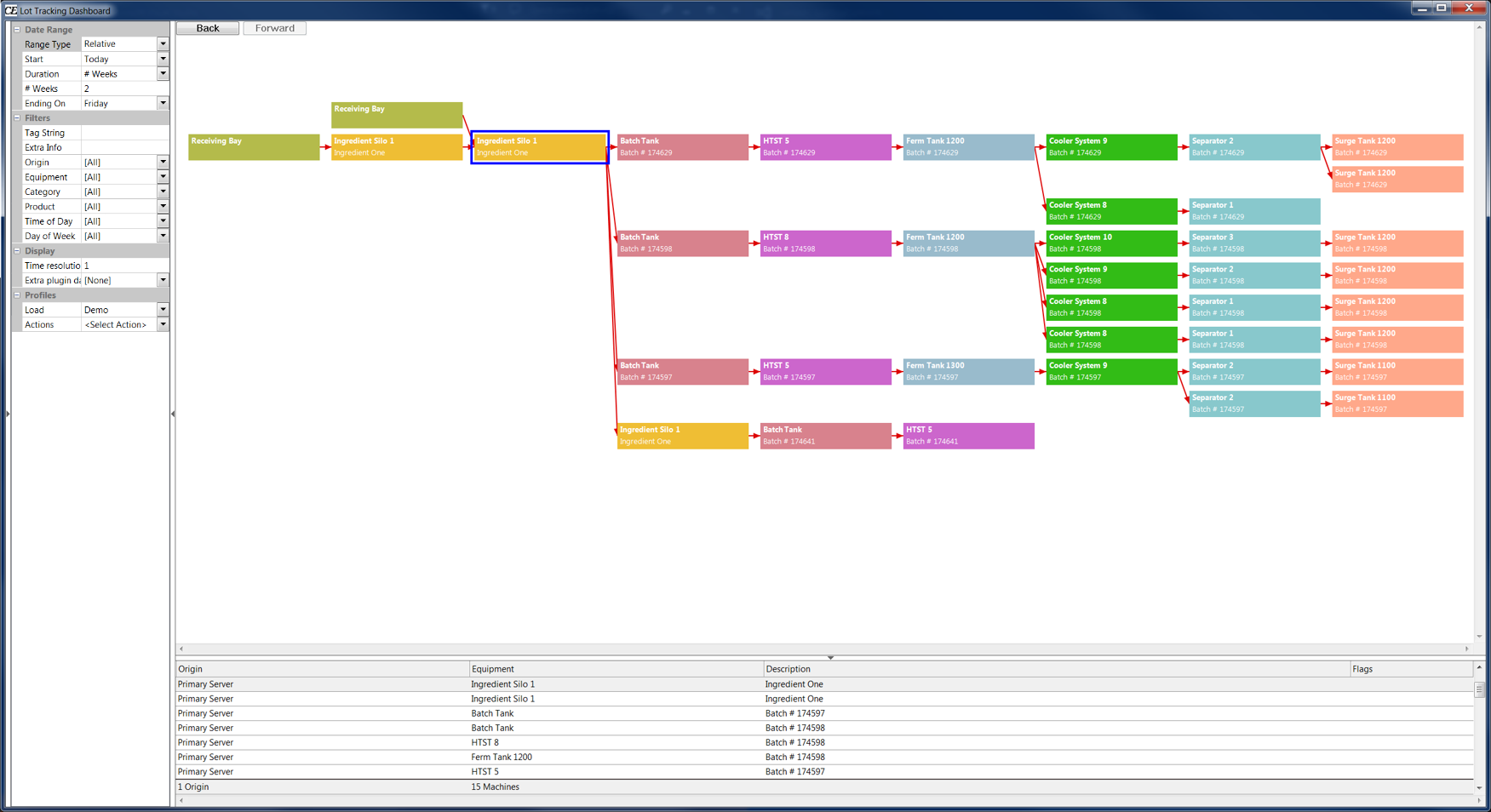

Track HD

- For a specific batch, its entire process genealogy can be identified and displayed on demand

- Raw material lot numbers are saved and tracked along with each batch

- Lot Tracking makes it simple to trace a finished product backwards through the production process to its origins

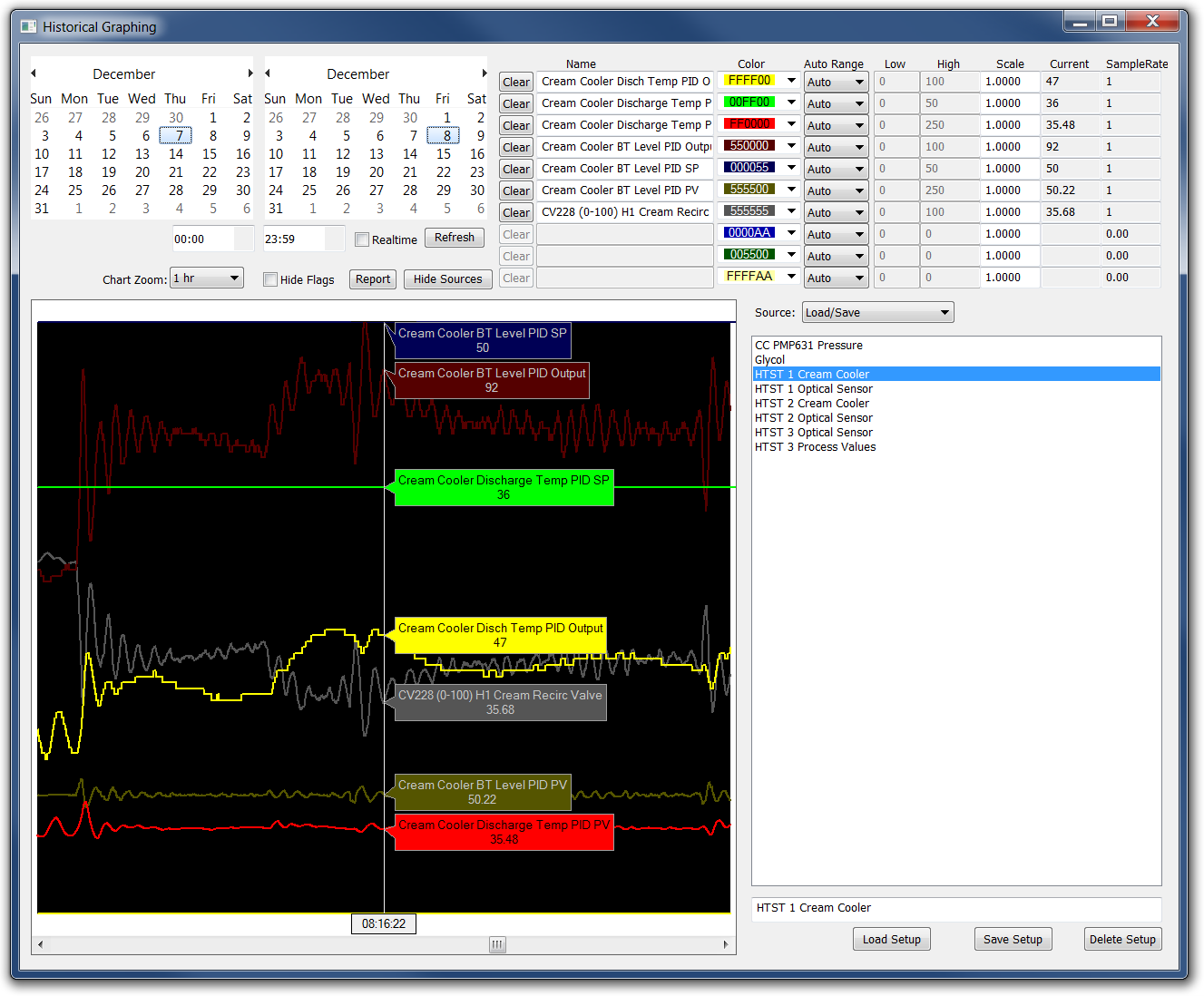

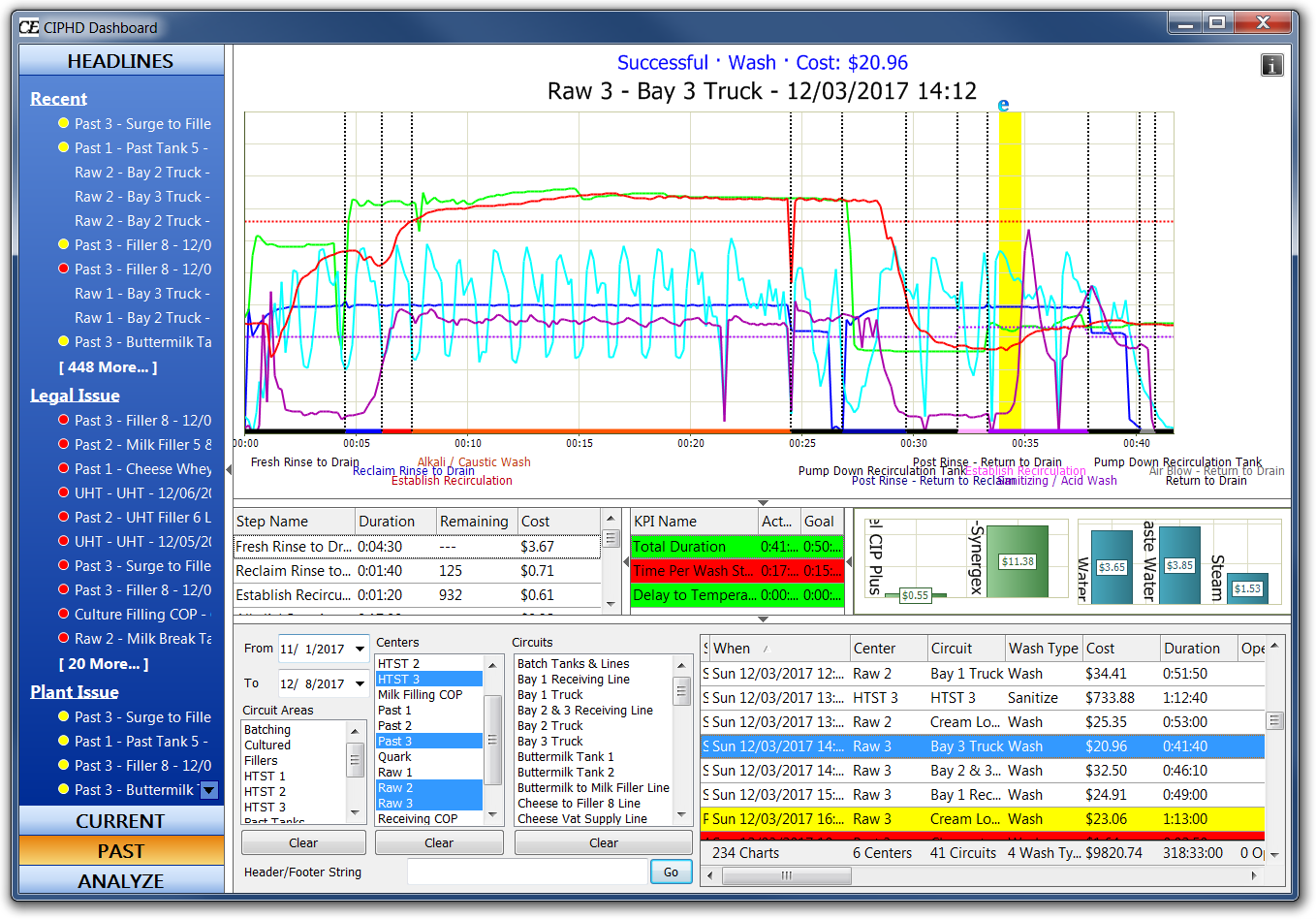

CIP HD

- Robust Data Capture Tool

- Interactive chart

- Chemical & Utilities tracking

- Benchmark against ideal chart

- Exception reporting

- Electronic signatures

- KPI tracking

- Robust Data Analytics

- Aggregate wash data

- Generate user defined reports

- Off the Shelf & Scalable

- Integrates into any plant

- Doesn’t interfere with control sys.

- No custom programming

- 100% FDA Compliant

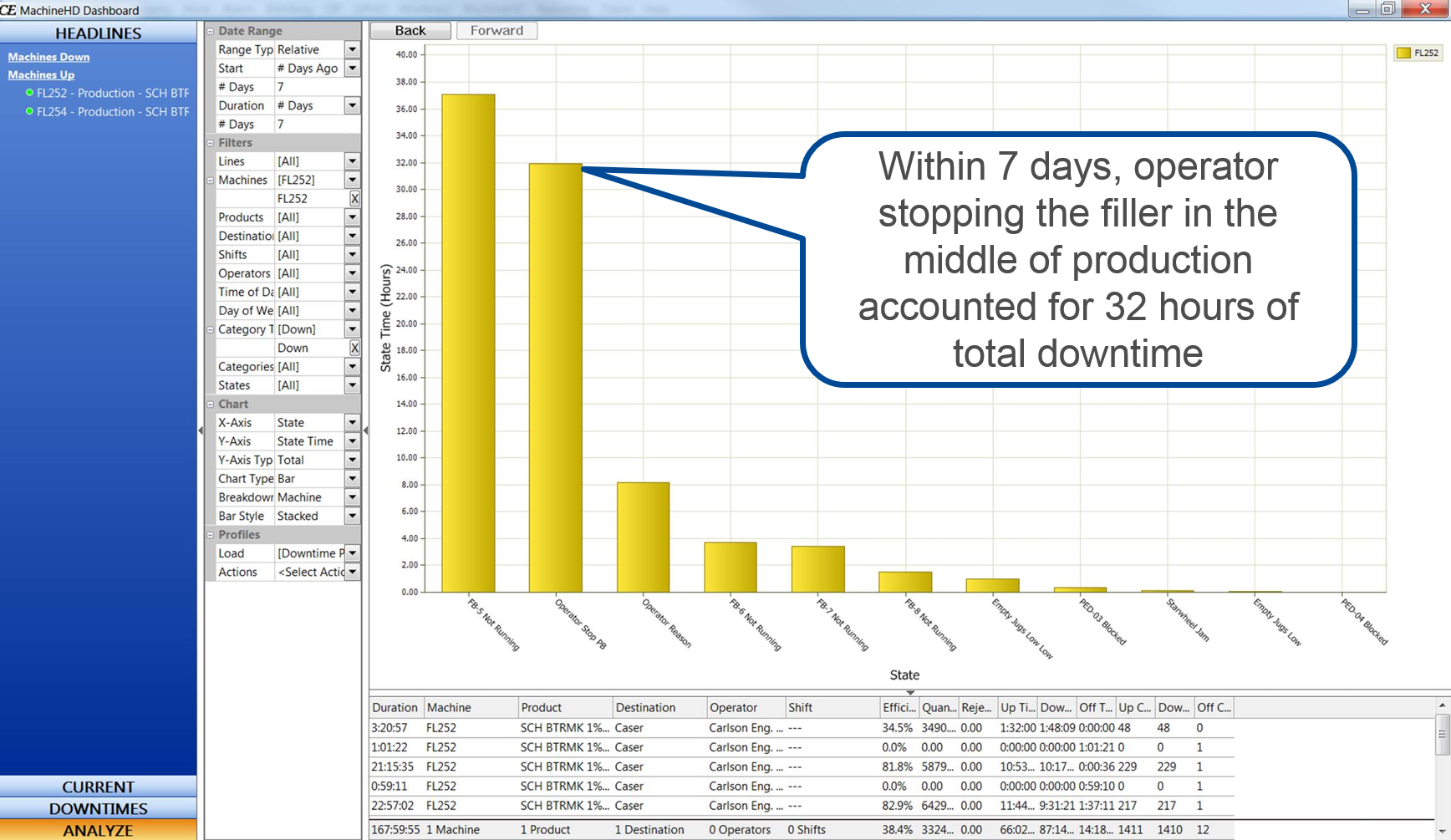

Machine HD

- The built-in Machine Utilization summarizes all downtime events in an easy to read report

- Reports are organized into major causes of downtime so managers are empowered to identify and correct root cause

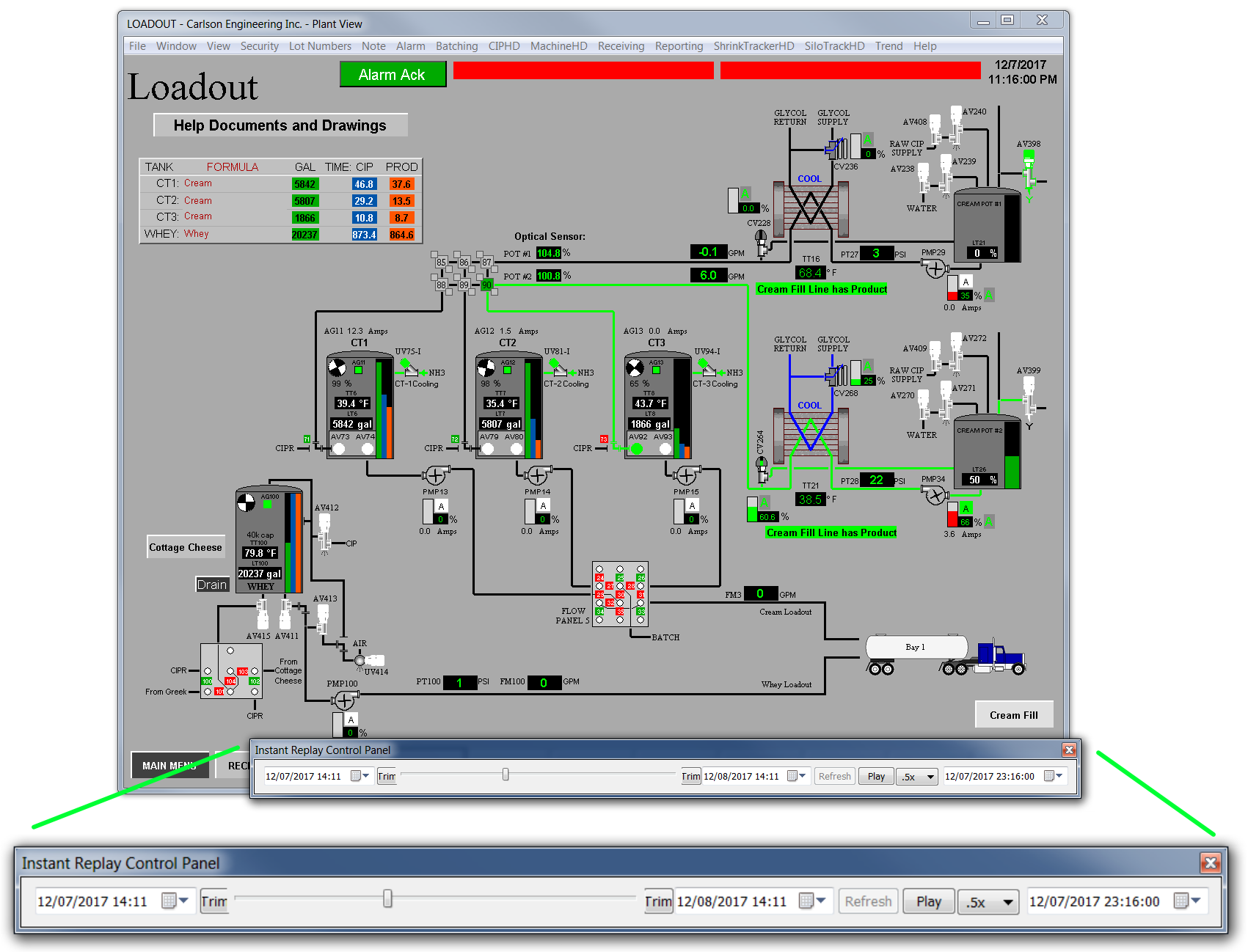

Instant Replay

- Captures Any Event

- Data collection for all PLC initiated commands

- Data collection for all device feedback

- Secure storage for multi year

- Replay HMI Screen

- Display any event in real time

- Stop, slow, rewind

- Diagnose issues on the fly

- Validate corrective actions

- Off the Shelf & Scalable

- Integrates into any plant

- Doesn’t interfere with control system

- Ideal training tool